SAND CASTING

Process Introduction

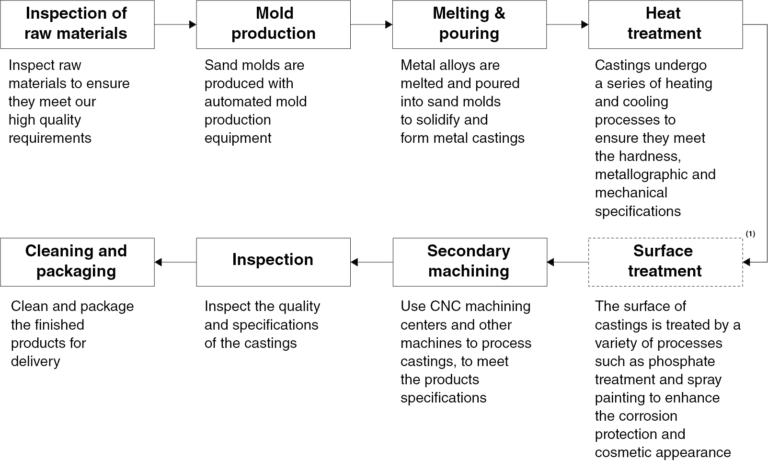

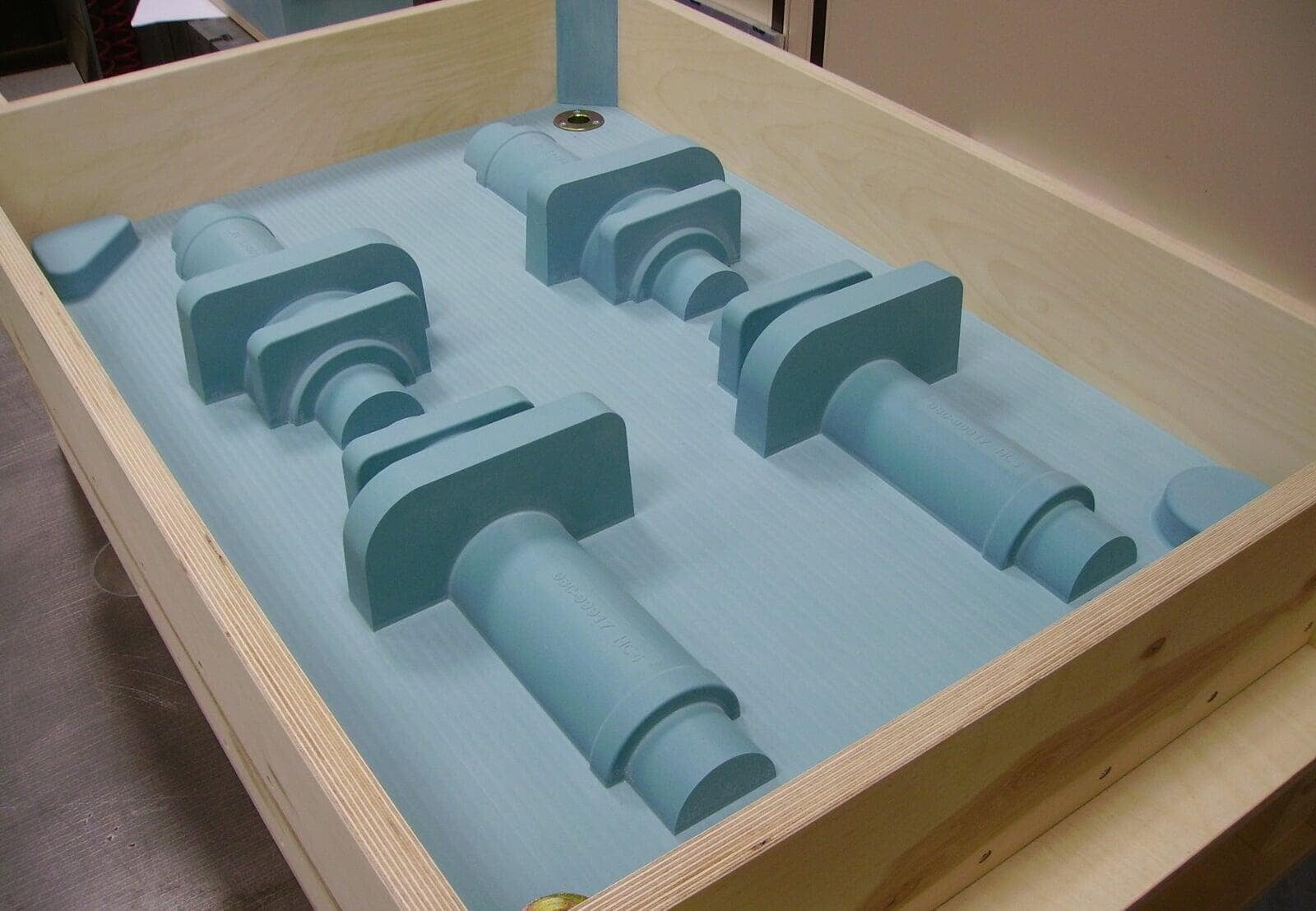

Sand casting is a metal forming process in which a mold is first formed from a three-dimensional pattern of sand, and molten metal is poured into the mold cavity for solidification. The sand shell is subsequently removed after the metal components cooled and formed. Certain sand casting components require a secondary machining process after casting. Sand casting can process a wide range of metals and alloys, including iron, special alloy steel, titanium alloy, and others. Sand casting is a cost-effective and efficient technology, which is generally flexible with regards to size and change of geometry design. Secondary machining is usually needed to improve product accuracy.

PRODUCT GALLERY

QUALITY MACHINED AND CAST

At Marvel Enterprises, we take pride in delivering products that epitomize superior craftsmanship and precision. Our quality machined components are meticulously engineered to meet the highest standards of performance and durability. Each piece undergoes rigorous testing to ensure it functions flawlessly in demanding environments.

ISO CERTIFIED

IN-HOUSE PATTERNS

HI-GRADE RAW MATERIAL

TEAMS OF EXPERTS

Integrated Capabilities

Integrated Capabilities

Design & Engineering

Design & Engineering

Mechanical Manufacturing

Mechanical Manufacturing

Machining Services

Machining Services

Ferrous Casting

Ferrous Casting

Heat Treatment Furnace

Heat Treatment Furnace

Spectro Analysis

Spectro Analysis

Commitment to Sustainability

At Marvel Enterprises, we recognize the importance of sustainability in today’s industrial landscape and are committed to integrating environmentally responsible practices into our operations. From sourcing raw materials to our manufacturing processes, we strive to minimize our environmental footprint by reducing waste, conserving energy, and optimizing resource efficiency. Our focus on sustainability extends to the longevity and durability of our products, ensuring that our high-quality crusher spares and components contribute to reduced environmental impact through their extended lifespan and reliable performance. We are dedicated to continually improving our practices, adopting innovative technologies, and working towards a greener future for the industry and the communities we serve.

MATERIAL WE MANUFACTURE

At Marvel Enterprises, we specialize in manufacturing high-grade materials specifically designed for the crushing and heavy-duty industries.

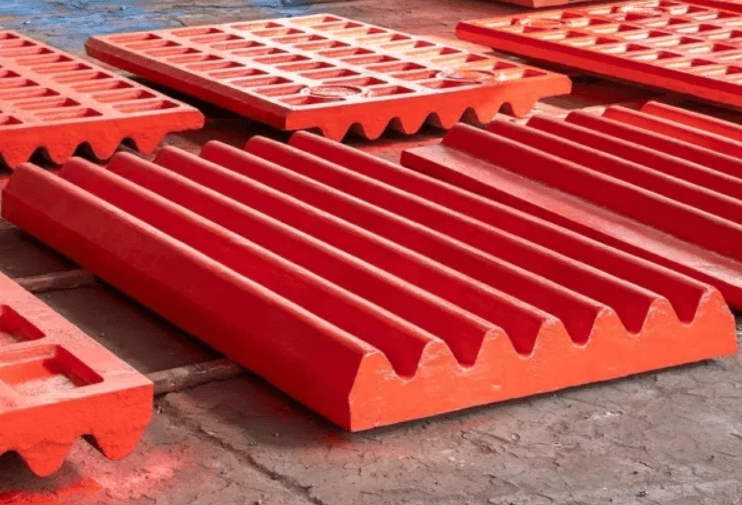

Manganese Steel Casting

At Marvel Enterprises, manufactures ASTM A128 standard manganese steel wear parts over 12,000 tons per year , which products include cone crusher liners, jaw crusher liners, mill liner, hammer mill and other wear parts. Our primary Grade 7 magnesium steel, containing 16% manganese, conforms to industry standards for wear resistance, toughness, and strength, making it particularly suited for stone crushing, mining, and heavy industrial use

Carbon Steel Casting

At Marvel Enterprises, carbon steel castings designed to meet stringent industry standards for strength, toughness, and durability. We offer carbon steel (ZG250-700,ZG20SiMn,G20Mn5,ASTM A148,ASTM A488 ,ASTM A781 ,ASTM A802) wear parts, which include cone crusher shell , jaw crusher flywheel, pitman, adjustment ring. and other parts

Alloy Steel Casting

Our advanced manufacturing processes and stringent quality control measures ensure that our alloy steel castings deliver superior performance. Material include Cr-Mo alloy steel, 30crNiMo alloy steel , heat resistant alloy steel . products include alloy mill liners, alloy hammers, heat resistant liners